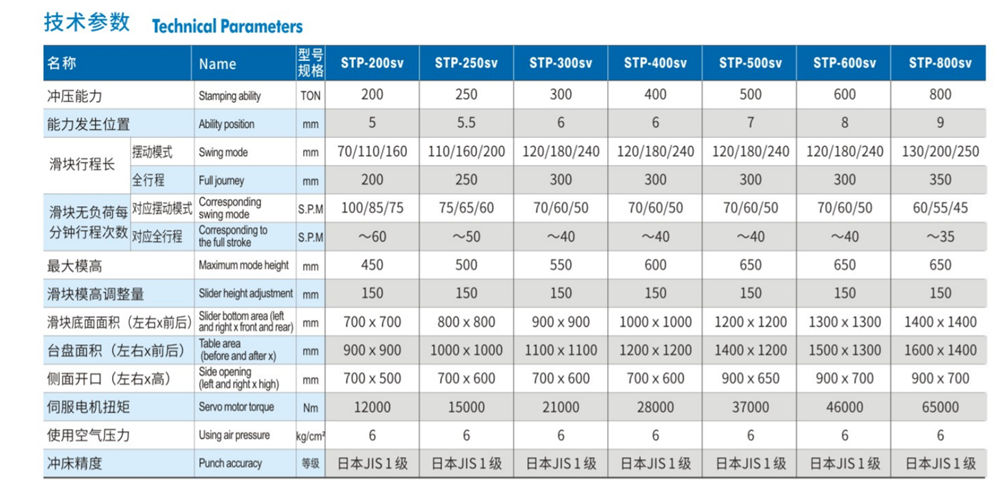

Madaidaicin Side Servo Press (STP jerin)

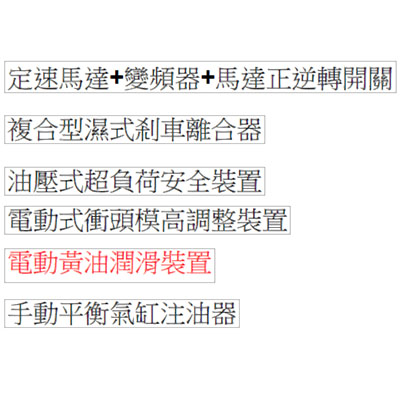

Babban halayen aiki:

Fuselage yana da tsayayyen tsaurara (nakasawa) 1/15000, ƙaramin nakasawa, lokacin riƙewa daidai, daidaitaccen samfuran samfuran, ƙaramar dawowa, kuma zai iya ɗaukar manyan abubuwa.

Yi amfani da birki mai ɗauke da rigar pneumatic, kare muhalli, babu gurɓatawa, ƙara amo, tsawon rai.

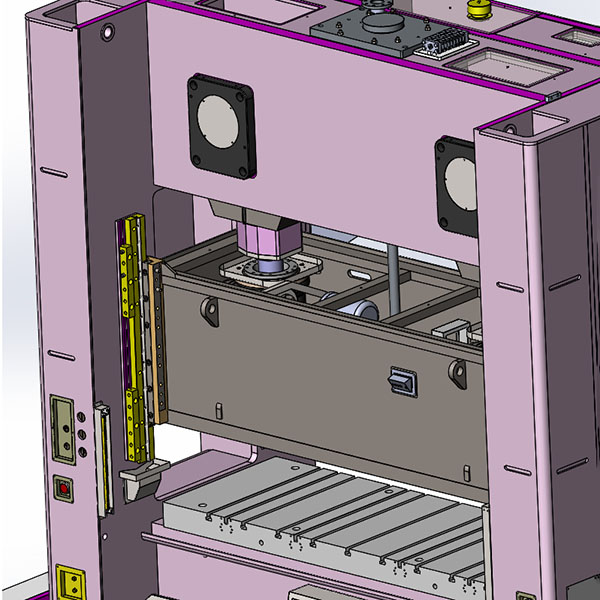

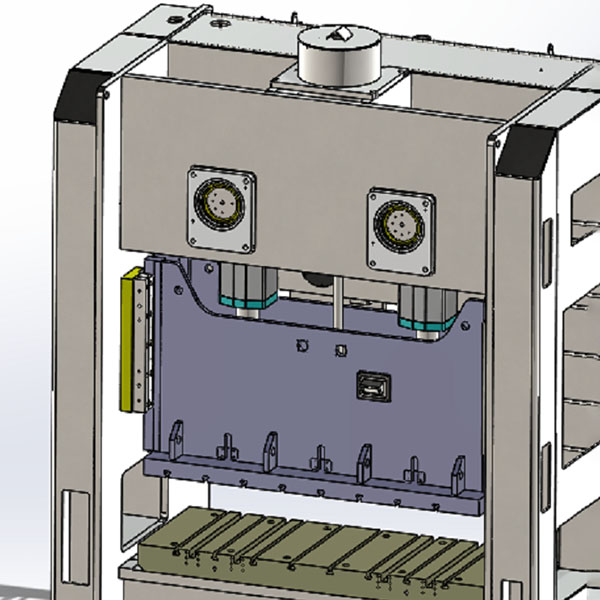

Siffar ta ɗauki hanyar jagora mai kusurwa huɗu da takwas, waɗanda zasu iya ɗaukar babban kaya mai haɗari: don tabbatar da dogon lokaci da kwanciyar hankali na daidaitaccen hatimi.

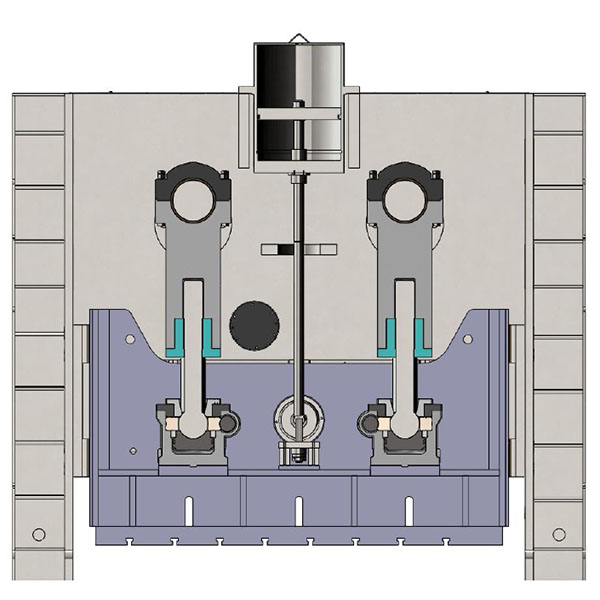

Jagoran silsilar jagorar dogo yana ɗaukar "ƙararraki mai saurin-ƙarfi" da "aikin narkar da layin dogo", tare da ƙaramin lalacewa, daidaitaccen tsari, lokacin riƙewa na daidaitaccen tsari, da ingantaccen rayuwar mai canzawa.

An karɓi kayan shafa mai na bakin ciki wanda aka tilasta shi, wanda ke da ƙarfin-kuzari, ya dace da muhalli, kuma yana da aikin ƙararrawa ta atomatik. Za'a iya ƙara yawan hatimi ta daidaita adadin mai.

Crankshaft an yi shi ne da kayan haɗi mai ƙarfi mai ƙarfi 42CrMo, wanda yake da ƙarfi sau 1.3 fiye da ƙarfe 45 kuma yana da tsawon rai.

Hannun tagulla an yi shi ne da tagulla-tagulla ZQSn10-1, wanda ƙarfinsa ya ninka sau 1.5 fiye da na farin na BC6 na tagulla. Yana amfani da na'urar kariya mai karfin gaske, wanda zai iya kare rayuwar sabis ɗin naushi da mutu.

Na'urar firikwensin tashar tashoshi 4 da aka shigo da su na iya gano (nunawa) nauyin samfurin da aka buga a ainihin lokacin, kuma bugun zai tsaya kai tsaye idan ya zarce nauyin don kare naushi da ƙirar.

Misalin Jafananci SMC mai sarrafa bawul, lubricator, tace iska.

Bayanai na Japan na NSK na Japan da hatimin NOK na Japan.

Daidaitaccen daidaito na Jamusanci Siemens PLC, Siemens allon tabawa, Siemens motor, Jamusanci SICK grating matakin huɗu, SICK encoder.

Daidaitaccen daidaitawa

DAYA madaidaiciya gefe biyu crank punch press

VS

Sauran madaidaiciyar gefen biyu crank presses

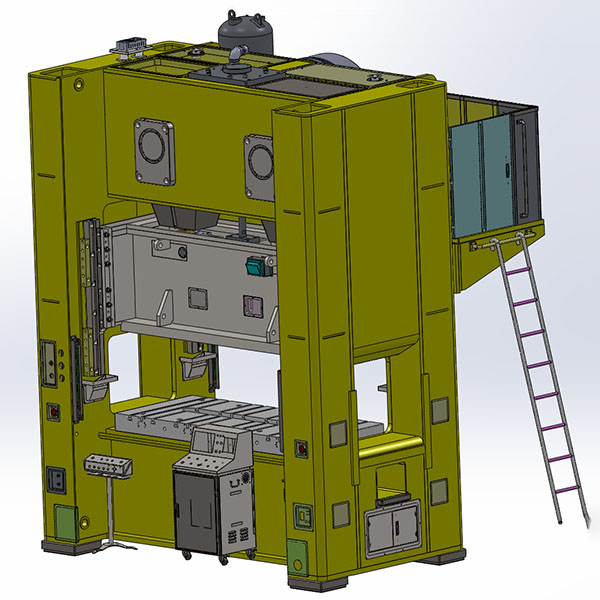

Daya latsa

Daya latsa: tare da dandamali da shinge masu aminci, masu dacewa don kulawa da kamawa da canjin mai mai sanyaya, babban bel ɗin motar yana kwance kuma yana da sauƙin daidaitawa, kuma ya dace da kiyayewa mai zuwa. Mafi aminci kuma mafi dacewa.

Sauran latsa

Sauran latsa:Ba tare da dandalin kulawa ba. Kulawa da kamawa, maye gurbin mai mai sanyaya, daidaita madauri na babban bel, da sauransu wanda za'a iya kammala shi kawai tare da taimakon forklift, wanda bai dace da gyara da kiyaye shi ba. Akwai wasu haɗari masu haɗari na aminci.

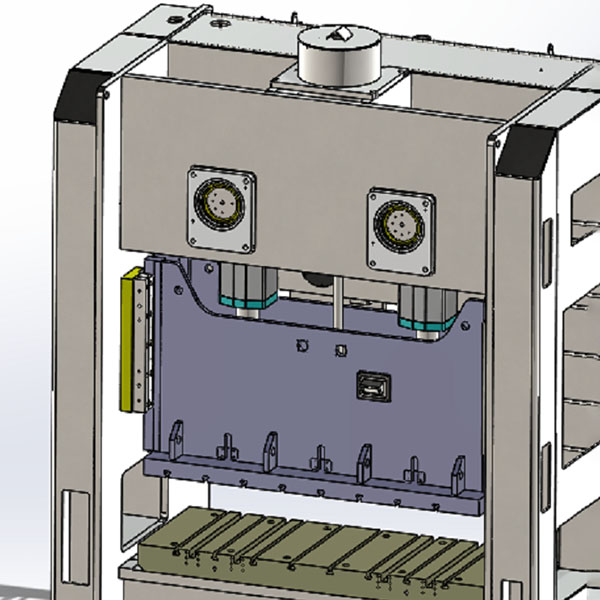

Daya latsa

Daya latsa: Daya press ta ɗauki kusurwa huɗu da gefuna takwas don kewaye layin dogo. A cikin matsayin kafa tambari, dogo mai shiryarwa ya haɗa da duk rails masu jagora akan jikin tebur. Wannan nau'in dogo mai shiryarwa yana da halaye na daidaitaccen hatimi, ƙarfin haɓakar haɓakar haɓaka, ƙaramin dogo da dogon lokacin riƙewa.

Sauran latsa

Sauran latsa:dogo mai shiryarwa tare da tsarin kewaye kamar yadda aka nuna a cikin adadi mai kyau an karɓa. Yayin aikin hatimi, akwai ɓangaren hanyar dogo da aka fallasa. A yayin aikin hatimi, dogo mai shiryarwa yana da sauƙin karkatarwa, tare da ƙarancin nauyin nuna son kai, ƙarfin dogo, gajeren lokacin riƙewa da tsadar kulawa.

Daya latsa

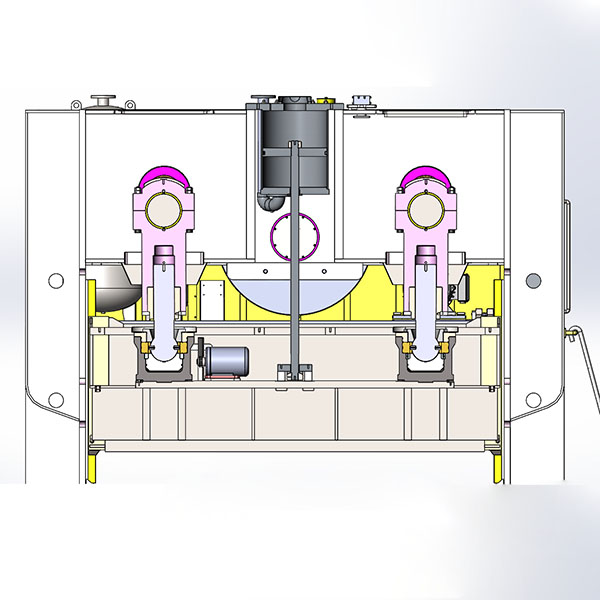

Daya latsa: nesa tsakanin maki biyu na amfani da karfi ya fi 60%; Fa'idodi: mafi girman nisa tsakanin maki biyu na aikace-aikacen karfi, mafi girman karfin ɗaukar nauyi; mafi girman tazarar da ke tsakanin maki biyu na aikace-aikacen karfi, wanda ya fi tsadar farashin.

Sauran latsa

Sauran latsa:tazarar da ke tsakanin maki biyun ba ta wuce kashi 50% ba; Rashin fa'ida: karami nesa tsakanin maki biyu na aikace-aikacen karfi, karami karfin karfin tasirin aiki. Dogo mai sauƙin jagora yana da sauƙin karkatarwa, hanyar jagora tana da sauƙin sawa, kuma madaidaicin layin dogo mara kyau.

Daya latsa

Daya latsa: tilasta bakin ciki mai zagayawa tsarin, makamashi ceto, za a iya sake yin fa'ida, fan thermal yi ne mai kyau, idan aka kwatanta da man shafawa za a iya ƙara ta 5-10 beats a minti daya.

Sauran latsa

Sauran latsa: famfon man shafawa na lantarki, ba za a iya sake amfani da man shafawa ba, ba wani fa'ida ta tilasta tsarin bazuwar mai.

Daya latsa

Daya latsa: lokacin da tsayin bugun ya zama daidai, tsarin sikirin mai mai sihiri yana da inganci sosai, idan aka kwatanta shi da man shafawa, zai iya ƙaruwa 5-10 a minti daya. Yi cikakken bin matakin JIS na Jafananci na 1; daidaitaccen matakin JIS na Japan ya fi daidaitaccen matakin Taiwan CNS na 1.

Sauran latsa

Sauran latsa:famfon man shafawa na lantarki, ba za a iya sake amfani da man shafawa ba, babu fa'idar amfani da tasirin wurare dabam dabam na mai. a cewar Taiwan CNS matakin 1 misali

Jagorar faifai na Daya buga latsa

VS

sauran jagororin nunin naushi

Daya latsa

Sauran latsa

Jagoran dogo na buga naushi daya

1.High mai saurin bugu: taurin sama da hrc48;

2. Tsarin nika na dogo mai jagora: gamawar saman zai iya kaiwa ra0.4-ra0.8 (saman madubi), shimfidawa, daidaici da daidaito tsakanin 0.005mm / ㎡.

3. Kayan aikin inji yana da fa'idodi na ƙaramin lalacewa, ƙayyadadden ƙayyadadden lokaci, daidaitaccen lokacin kiyayewa, tsawon rayuwar sabis da ƙarancin makamashi.

Sauran layin jagorar dogobabu tsarin kashewa; aikin niƙa, yanayin rashin ƙarfi ra1.6-ra3.2, flatness, daidaici, daidaitacce fiye da 0.3mm / ㎡

Daya latsa crankshaft

VS

sauran latsa crankshafts

Daya buga latsa: an yi crankshaft da babban ƙarfin gami mai ƙarfi 42CrMo Ab Adbuwan amfãni: ƙarfin ya ninka sau 1.3 sama da na ƙarfe 45, rayuwar sabis tana da tsawo, juriya da lalacewa tana da kyau, lalacewar ƙarami ce, kuma an daidaita daidaito na dogon lokaci.

Sauran latsawa: an yi shi da ƙarfe 45, Rashin fa'ida: rashin tsada , ƙarfi da juriyar lalacewa ba su kai kwatankwacin 42CrMo

Daya

Hanyar mai na DAYA naushi PRESS: Used 8 ana amfani dashi don bututun mai na shafa mai.

Abvantbuwan amfani: dogon bututu, babban diamita ba sauki a toshe, fasa, tabbatar da amincin man shafawa, mai santsi.

Sauran

Sauran latsawa: bututun mai na man shafawa na latsa ya ɗauki Φ 6.